Nice post. Glad to see you giving thanks when most, including me, would whine.

Car looks good and glad it's on the road. Remember I'm close to denver and always willing to help out...anything to keep those Mustang wheels off your car! Never thought of sagging the drive with the avalanche and carrying parts or whatever for all of you.

Build thread

Re: Build thread

It must be going around, I got a nail in my wagon tire this morning. I am glad that wasn't your new wheel/tire setup that would be an expensive issue.

Glad its on the road though, what is the likelihood of making the next track day?????

Looked like a fun cruise and get together, sad I had to work and missed out on it.

Glad its on the road though, what is the likelihood of making the next track day?????

Looked like a fun cruise and get together, sad I had to work and missed out on it.

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

Shadowden wrote:Nice post. Glad to see you giving thanks when most, including me, would whine.

Car looks good and glad it's on the road. Remember I'm close to denver and always willing to help out...anything to keep those Mustang wheels off your car! Never thought of sagging the drive with the avalanche and carrying parts or whatever for all of you.

Well this kinda stuff happens, and it's hard to not be thankful for so many things going right in a time like that when just one thing went wrong. It sucks losing a brand new tire but I saved money getting the car home without having it towed. And at least it wasn't one of the wheels/tires that I've been trying to put on lol.

Thanks! The truck in the pic is Ivan's dad, Ivan Sr lol. Ivan Jr has the other white FC vert in the pic, the one right next to my car. His radiator cracked when we got to the intersection of 126 and 285. So they left the car up there, drove home to get the trailer, and went back and hauled it home. Luckily he shut it down right away.

Brett's FC had idling issues before we got on the first part of the drive so he took it home and got his CTS-V and met us on 470 on the way to Unser.

It was like an episode of Survivor, we each had to leave the island at some point lol.

Dwduc wrote:It must be going around, I got a nail in my wagon tire this morning. I am glad that wasn't your new wheel/tire setup that would be an expensive issue.

Glad its on the road though, what is the likelihood of making the next track day?????

Looked like a fun cruise and get together, sad I had to work and missed out on it.

It really freaks me out now thinking about getting stuff in my tires, especially if I'm on a long trip like going back home by myself. I don't have a spare, I haven't had my little compressor with me but I will now, along with a can of fix a flat and a plug kit. Yeah it would have made me more mad if it was the new wheels since it would have been yet another setback lol. Chris emailed me yesterday and said my logs don't have a whole lot of information but he's going to send a map for me to try. I doubt I'll be ready for track days this year, unfortunately. I still need to get a seat rail made too. Yeah it was a blast, too bad you couldn't make it. Hopefully we'll do it again a couple times before the end of summer.

Oh, another thing I noticed last night on the way home was my oil temps got down to 132F and coolant temps down to 165F. I had removed the condenser when I was getting the lines made and decided to leave it off for the drive. With the condenser I usually see about 185F coolant temps. I'm going to make a splitter for the front of the condenser to force more air to the radiator. And also duct the whole VMIC.

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

I've been waiting for the spacers to come in and in the mean time working on getting the AC lines finished and tonight I realized I could use most of the old pieces for ducting, so I started installing them.

I had Whisler Bearing make one of the AC lines, I think I mentioned that already. Wednesday I dropped off the AC lines at Maxair in Denver so they could modify them to work with my system. They were finished yesterday so I went to pick them up but I made a mistake explaining what I needed on the high pressure line that crosses across the engine bay and they swapped the fitting on the wrong end, so I only brought back two of the lines and left that one for them to fix. They called this morning and said they can't modify it because there isn't enough room on one end of the line to weld the fitting on there and asked if I could use it that direction and just extend the wiring harness to the sensor. I'm going to take the car up next week so there won't be any more mistakes. Here is what the lines and dryer look like so far. I'm not really crazy about the size of the soft lines, and I prefer the sleeker, smaller look of the hard lines, so I'm thinking about trying to remake them some other time, providing the AC system works well. And I plan on using R12 instead of R134a.

I plan on working on the ducting tomorrow. I'd rather do all fiberglass, but I'm not sure if that's going to happen. I'm going to make the splitter for the leading edge of the condenser to direct more air directly to the radiator, below the condenser.

I had Whisler Bearing make one of the AC lines, I think I mentioned that already. Wednesday I dropped off the AC lines at Maxair in Denver so they could modify them to work with my system. They were finished yesterday so I went to pick them up but I made a mistake explaining what I needed on the high pressure line that crosses across the engine bay and they swapped the fitting on the wrong end, so I only brought back two of the lines and left that one for them to fix. They called this morning and said they can't modify it because there isn't enough room on one end of the line to weld the fitting on there and asked if I could use it that direction and just extend the wiring harness to the sensor. I'm going to take the car up next week so there won't be any more mistakes. Here is what the lines and dryer look like so far. I'm not really crazy about the size of the soft lines, and I prefer the sleeker, smaller look of the hard lines, so I'm thinking about trying to remake them some other time, providing the AC system works well. And I plan on using R12 instead of R134a.

I plan on working on the ducting tomorrow. I'd rather do all fiberglass, but I'm not sure if that's going to happen. I'm going to make the splitter for the leading edge of the condenser to direct more air directly to the radiator, below the condenser.

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

I started mocking up some molds for the VMIC ducting, but I haven't started fiberglassing yet. Maybe tomorrow night. I think I have a pretty good plan for the pieces though. I'm making one piece to cover the radiator and condenser, and another piece to extend to the frame on the passenger side to channel air for the filter. Then I'll make the ducting for the intercooler, but I'm not sure yet if I want to do it in one piece or three. This is the only one I have mocked up right now.

I got the spacers today so I put those and the track wheels on this afternoon and took it for a drive. I like it.

I got the spacers today so I put those and the track wheels on this afternoon and took it for a drive. I like it.

Re: Build thread

Just cool to read you are getting to drive your car!

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

Yeah I really love how it's set up now.

I took it to Denver today and had planned on picking up the AC line, but when I was talking to the guy I had an epiphany and asked him to cut the ends off (cut before the sensor on the one end) and swap them that way, so that's what they're doing right now. It might be ready by tomorrow. Then I did some research tonight about refrigerants and I believe I'm going to charge it myself with some R12a, aka ES12, aka probably a ton of other names lol. Anyway, I was reading this thread.

http://www.968forums.com/topic/905-my-e ... rigerants/

And at the bottom of the first post is a link to where he got his refrigerant. I think I'll either get the ES-12a/134a or industrial R12.

http://autorefrigerants.com/hydrocarbon-refrigerants

Now I'm just trying to decide if I want to go ahead and swap to R-134a fittings or keep the original R12. I'd like to see if I can get it leak tested before I charge the system.

On the highway I cruise in 5th gear around 80mph, right where the dead spot is on the map. So needless to say it's been pissing me off. I stopped by PCS downtown to see if they have tuned any Syvecs ECUs and the tuner, Travis, said he has on a GTR but it's been a couple years. They deal mainly with Porsche now and since Syvecs makes ECUs specifically for Porche I figured it was a good shot. I scheduled August 1st for him to tune the car. This summer is slipping by without a good tune on the car and I'm starting to get angry about that. I told him the fuel map just needs to be adjusted a bit, so hopefully it won't take too long. If Chris gets something done before then I'll cancel the tuning session, but at this point I'm not holding my breath.

I took it to Denver today and had planned on picking up the AC line, but when I was talking to the guy I had an epiphany and asked him to cut the ends off (cut before the sensor on the one end) and swap them that way, so that's what they're doing right now. It might be ready by tomorrow. Then I did some research tonight about refrigerants and I believe I'm going to charge it myself with some R12a, aka ES12, aka probably a ton of other names lol. Anyway, I was reading this thread.

http://www.968forums.com/topic/905-my-e ... rigerants/

And at the bottom of the first post is a link to where he got his refrigerant. I think I'll either get the ES-12a/134a or industrial R12.

http://autorefrigerants.com/hydrocarbon-refrigerants

Now I'm just trying to decide if I want to go ahead and swap to R-134a fittings or keep the original R12. I'd like to see if I can get it leak tested before I charge the system.

On the highway I cruise in 5th gear around 80mph, right where the dead spot is on the map. So needless to say it's been pissing me off. I stopped by PCS downtown to see if they have tuned any Syvecs ECUs and the tuner, Travis, said he has on a GTR but it's been a couple years. They deal mainly with Porsche now and since Syvecs makes ECUs specifically for Porche I figured it was a good shot. I scheduled August 1st for him to tune the car. This summer is slipping by without a good tune on the car and I'm starting to get angry about that. I told him the fuel map just needs to be adjusted a bit, so hopefully it won't take too long. If Chris gets something done before then I'll cancel the tuning session, but at this point I'm not holding my breath.

Last edited by speedjunkie on Fri Jul 15, 2016 9:14, edited 1 time in total.

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

I went to Denver and picked up the line today. And it was then that I realized my great epiphany last night was not much more than a massive brain fart. Basically what I asked them to do was UNDO what they had done the first time, and now the line is again unusable. And I paid another $60 for that. I'm so done with this shit. I told him I'd just pay for it and I wasn't coming back because it's too far to keep running back and forth and they can't do what I need them to do anyway. I'm almost tempted to rip out all the AC stuff and just stick with it the way it is. I might run down to Whisler again and see if they have some kind of fittings that will make it work. Ugh.

- $crillaTor

- Senior Member

- Posts: 153

- Joined: Sat Jun 15, 2013 9:14

- Location: Colorado Springs

Re: Build thread

My pains with the AC weren't as bad as yours, but I completely understand where you're coming from. For whatever reason, just trying to get that AC system re-installed after the VMIC setup is a pain in the ass. It shouldn't be that hard but I got frustrated with it and gave up long before the point you have gotten to... I plan on tackling it again at some point, but I'm not sure if it will be this summer or not; just too much shit going on.

BTW - I really dig your new wheel setup. Looks great.

BTW - I really dig your new wheel setup. Looks great.

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

Yeah it's been a bigger task than I thought it would be. I've thought about making kits to sell once I get all this figured out.

If the Denso high pressure line will work with the MANA evaporator I'll be set, as long as I can find the lines I need.

Thanks! I really like how it turned out.

Chris sent me a map today but I haven't tried it yet. I did upload it to the ECU though. I was going to start on the fiberglass today too but wasted the whole day lol.

If the Denso high pressure line will work with the MANA evaporator I'll be set, as long as I can find the lines I need.

Thanks! I really like how it turned out.

Chris sent me a map today but I haven't tried it yet. I did upload it to the ECU though. I was going to start on the fiberglass today too but wasted the whole day lol.

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

I don't know if I mentioned it before but I bought a Bacon Motorsports oil pan. Len Bacon contacted me this morning and said it was finished and ready to ship so I sent the second payment.

I went to Whisler Bearing with the couple AC lines I'm having trouble with and the guy there in the hose shop found a fitting that works with the stock line, but he wasn't allowed to cut the fitting off that Maxair had put on since he didn't build it, so he gave me the number to a friend that has a mobile AC line assembly shop and he's going to change it out for me, possibly as soon as Wednesday but maybe as late as next week. And since my stock line is all jacked up now I bought a replacement from Fritz Flynn.

I also finally started the fiberglass work tonight. I'm gonna let it cure overnight and maybe add to it tomorrow.

I went to Whisler Bearing with the couple AC lines I'm having trouble with and the guy there in the hose shop found a fitting that works with the stock line, but he wasn't allowed to cut the fitting off that Maxair had put on since he didn't build it, so he gave me the number to a friend that has a mobile AC line assembly shop and he's going to change it out for me, possibly as soon as Wednesday but maybe as late as next week. And since my stock line is all jacked up now I bought a replacement from Fritz Flynn.

I also finally started the fiberglass work tonight. I'm gonna let it cure overnight and maybe add to it tomorrow.

Re: Build thread

Those oil pans look great! Do they have gates/flaps to keep oil near the pickup? Can't see the inside.

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

Yeah they have little doors, it kinda looks like they have springs but I can't tell. They are really nice. They have incorporated a lot of nice features.

-slosh protection

-two drains at the very back of the pan

-o-ring seal against the engine instead of a gasket or RTV

-the mounting flange as a whole is thicker to act as a brace, but machined thinner where the engine mounts bolt on so it doesn't raise the engine (this will allow me to put regular engine mounts back on AND use the tranny brace)

-slosh protection

-two drains at the very back of the pan

-o-ring seal against the engine instead of a gasket or RTV

-the mounting flange as a whole is thicker to act as a brace, but machined thinner where the engine mounts bolt on so it doesn't raise the engine (this will allow me to put regular engine mounts back on AND use the tranny brace)

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

I checked the fiberglass this morning and it was still tacky, unreal! So I set it in the sun and checked it again after lunch. STILL TACKY! But by the time I brought it in around 4pm it was cured. Turns out I barely used any hardener. It was still very flimsy, I think because I had hardly any resin on it. So I sanded it down with 60 grit and added another layer and a lot more resin and hardener. This time I DEFINITELY used enough hardener because it hardened before I was finished haha. I cut out what I needed and put it on the car so I could put on the side pieces and lay the fiberglass. I think I'm done for the night though. I'll lay the sides on tomorrow, then once those are cured I'll make the rest of the pieces in one piece and add several layers. Looks like I'll need more cloth, and possibly much more resin and hardener.

I'm also calling the AC guy tomorrow to see if he can crimp the line. I really hope so, I could possibly get the AC finished by this weekend. Although I need to order the refrigerant still.

I'm also calling the AC guy tomorrow to see if he can crimp the line. I really hope so, I could possibly get the AC finished by this weekend. Although I need to order the refrigerant still.

- speedjunkie

- Senior Member

- Posts: 5337

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

I called Joel Lane today about putting the new fitting on the AC line, so he did that today. Pretty cool guy. He owns a shop called Green Synchro, he works on VW and Karmann Ghia. I talked to him for a bit. So now I'm just waiting on the line coming from Fritz and I can install those. I'd like to leak test it before charging, but I'm not sure if that's possible. I really don't remember much from learning about HVAC in tech school. I never worked on it in my job lol. And I STILL need to order the refrigerant. I'm kinda waiting on getting the lines and making sure everything is good before I order that stuff though, and I'm not sure how much I need.

I also fiberglassed the sides onto the ducting tonight. It's curing now. Tomorrow I'll take it back off and try to add all the remaining layers while it's on the workbench. I made quite a mess with it on the car tonight. Luckily most of that mess was mitigated by prior planning, but I didn't account for a couple things, like resting my glove on the front bumper lol. I got that off with Acetone though. I'm kinda excited to get this done so I can get back to driving the car.

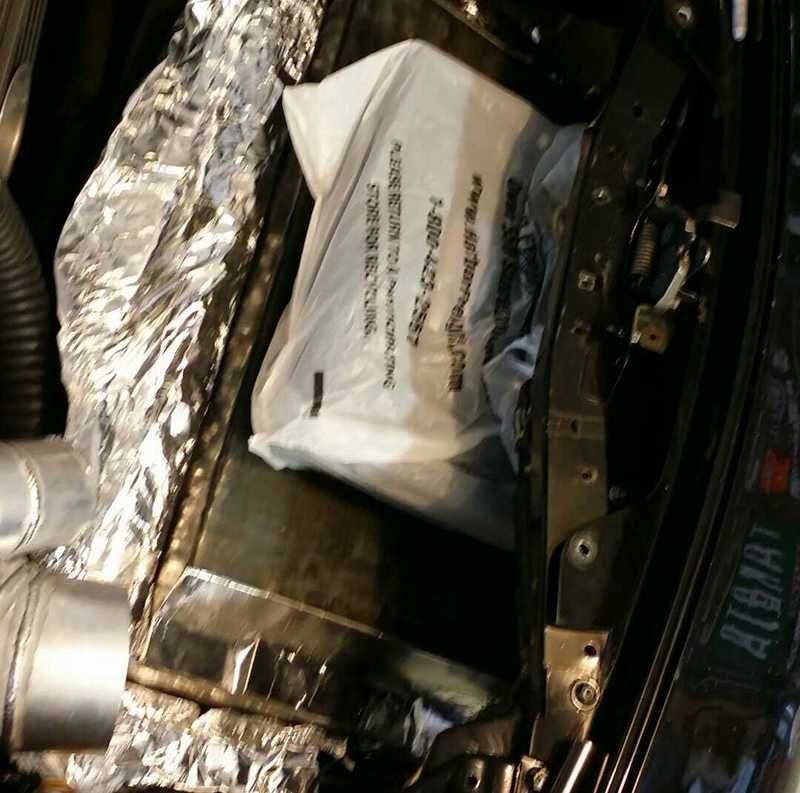

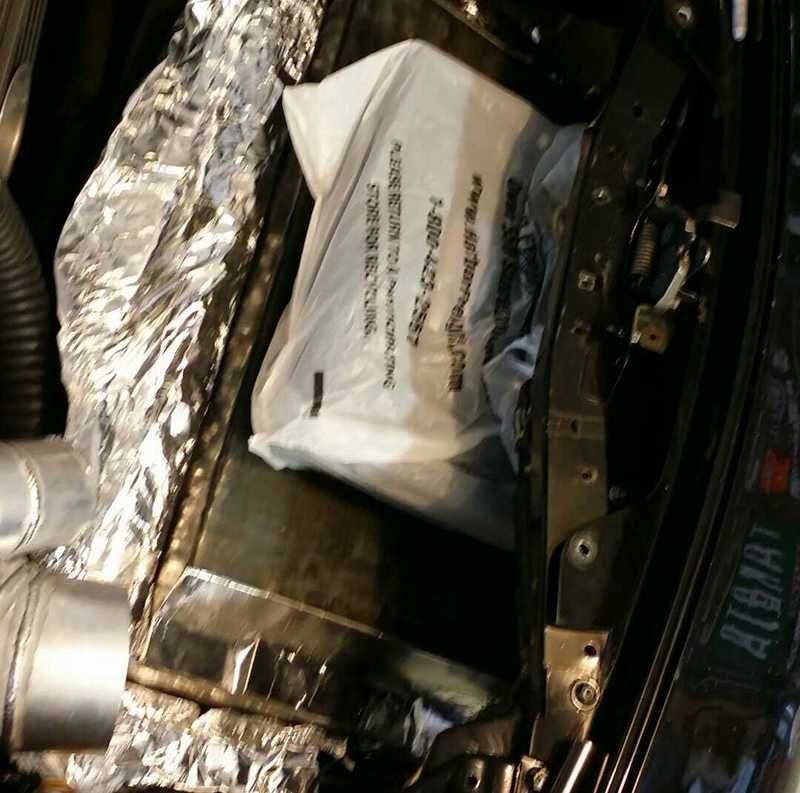

This pic is pretty blurry, but I used aluminum tape to block off the parts of the radiator and also to firm up the sides, which were cardboard.

I put three layers of cloth on. The first layer on each side I dipped into the resin, then I laid on a dry second layer and added more resin with a brush. Then I put on the third layer dry and added more resin with a brush again. Then I added more resin. And more resin lol. The bag on the top of the middle is holding a case of sockets to weigh down the middle of the duct. I pushed plastic bags into the void so it wouldn't sag but it forced the duct upwards, so I used the case to hold it flat.

I also fiberglassed the sides onto the ducting tonight. It's curing now. Tomorrow I'll take it back off and try to add all the remaining layers while it's on the workbench. I made quite a mess with it on the car tonight. Luckily most of that mess was mitigated by prior planning, but I didn't account for a couple things, like resting my glove on the front bumper lol. I got that off with Acetone though. I'm kinda excited to get this done so I can get back to driving the car.

This pic is pretty blurry, but I used aluminum tape to block off the parts of the radiator and also to firm up the sides, which were cardboard.

I put three layers of cloth on. The first layer on each side I dipped into the resin, then I laid on a dry second layer and added more resin with a brush. Then I put on the third layer dry and added more resin with a brush again. Then I added more resin. And more resin lol. The bag on the top of the middle is holding a case of sockets to weigh down the middle of the duct. I pushed plastic bags into the void so it wouldn't sag but it forced the duct upwards, so I used the case to hold it flat.

Who is online

Users browsing this forum: No registered users and 41 guests