Shadowden wrote:Did Chris build your harness? If so, then he would have put in a larger gauge wire. Otherwise, seems he would try to run the ground straight to battery ground.

Yes he did. Larger gauge wire for what? What are you referring to?

lOOkatme wrote:I didnt have much time to post last night.

Remember me talking about getting cold air to the intake and running a velocity stack and a large (low pressure drop) air intake filter.

All of this effort is to reduce the pressure ratio of the turbo. Same with feeding cold air into the intake. The whole idea behind running a large filter, velocity stack, and 3" open exhaust is to create the largest pressure differential across the turbo. These mods lower the pressure ratio of the turbo making it more efficient. Remember that your car right now is at sea level, coming up in altitude just makes the turbo work harder, make it suck through a HUGE straw and blow out a HUGE exhaust. little lost work.

Another thing to think about is turbine speed. I think you posted a max turbine speed, but think about how often you are actually at that speed. very little. I don't see that as a big deal.

Remember that driving the car is more about making the set up more fun to drive and for most that means more speed. More speed means higher risk, so anything that can reduce risk (crashing) and increase speed is a huge benefit. having a turbo with a wide powerband makes it easier to drive and will most likely be faster for the stuff we do even if it makes less peak power than another larger turbo. I wouldn't be dissapointed by having XXX WHP. think more about how easy the car is to drive. Hell, I am switching turbos for that very reason and I am literally just swapping to it for a broader powerband, not looking for more WHP. I also want to ditch the external wastegate.

Speed and safety is a function of predictability. The car performs the same every time and behaves in a way that if you are slightly wrong it is forgiving and able to recover easily. Stretched tires, softer rate springs, broad powerband I think is the key to going fast everywhere. I think you basically are setting up your car this way. everything else we do is trying to make the car more reliable. I think your set up is awesome and I am eager to see how it all fits together in the end. Keep in mind that this is all my opinion, and others like stiff spring rates, and more power.

closing statement. One thing that benefits absolutely everything in a cars performance and is somewhat skipped over by many is reducing weight. it helps in every single area of the cars performance and most overlook it. I might start looking at everything on my car and start dropping weight. Add weight to the spots that need it, drop it from where you don't.

Yes and I still plan on making that intake pipe, or at least trying it. I'm a little more limited on space than you are, so I can't go too big with a filter to fit over the stack. But I would like to optimize it if possible and I need to make a new pipe anyway. I'd still also like to go to a 4" downpipe at least, if not the midpipe and catback too.

I don't see the peak turbine speed as a big deal either, I just thought it was cool lol. And as long as I don't run into an overspeed situation, I'm not worried.

I'm not really disappointed by my numbers, it just wasn't as high as I figured it would be considering the new parts that are on there. But I would like to see just what it can do, how high it can get, while still being capable of the nice powerband it has. Even if I drop it down to a lower boost setting in the end. I'm more into the powerband than the numbers. However, I also don't want to get too crazy down low because if my tires just spin, what good is that? AND I'd be suffering top end for it. That's why I've been looking at the 8374. But if I can get these decent numbers and a great powerband out of the smaller 7670, and I don't have to do the work of swapping, I'm cool with that haha. I just want a well balanced car, as good as I can get it.

I'm definitely trying to set my car up that way. And you've done way more suspension tuning research than I have, and it's something I've always wanted to tackle but didn't know how, so I have no problem just copying your setup lol.

Dropping weight is something I definitely have skipped so far, and mostly that is because I'm not building it just for the track, but for comfort on the street as well. I used to love the Sport Compact Car Ultimate Street Car competition and I've tried to move in that direction a bit, making it an all around car and not just track or street. If I lose weight with some of the mods I'm definitely happy about that, but I know I've added some weight back in too. I want to weight it when I'm closer to finished just to see where it is compared to stock.

Alright here is some more chat between me and Chris over the past few days.

Chris wrote:I was going to suggest an oil thermostat but you already have one. So, yeah, I'd look at why it's not working correctly. The cooling system is impressive! The big oil coolers are the key I'd guess. That helps water temps big time as well.

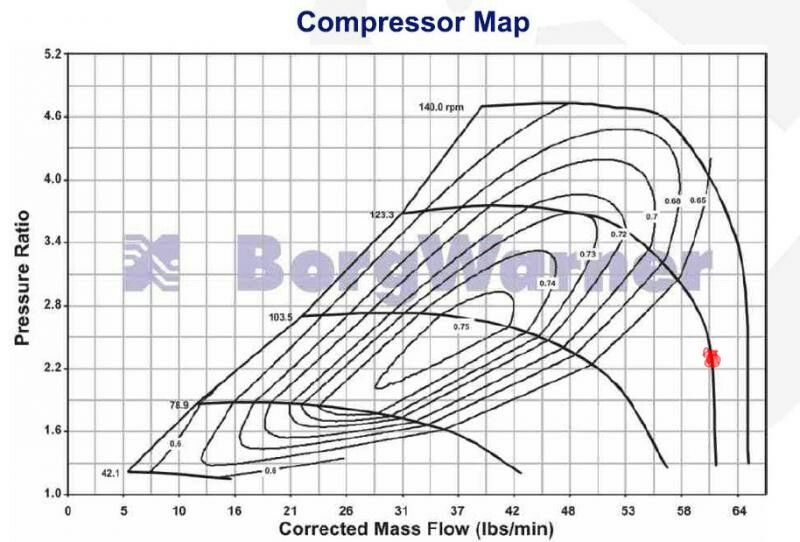

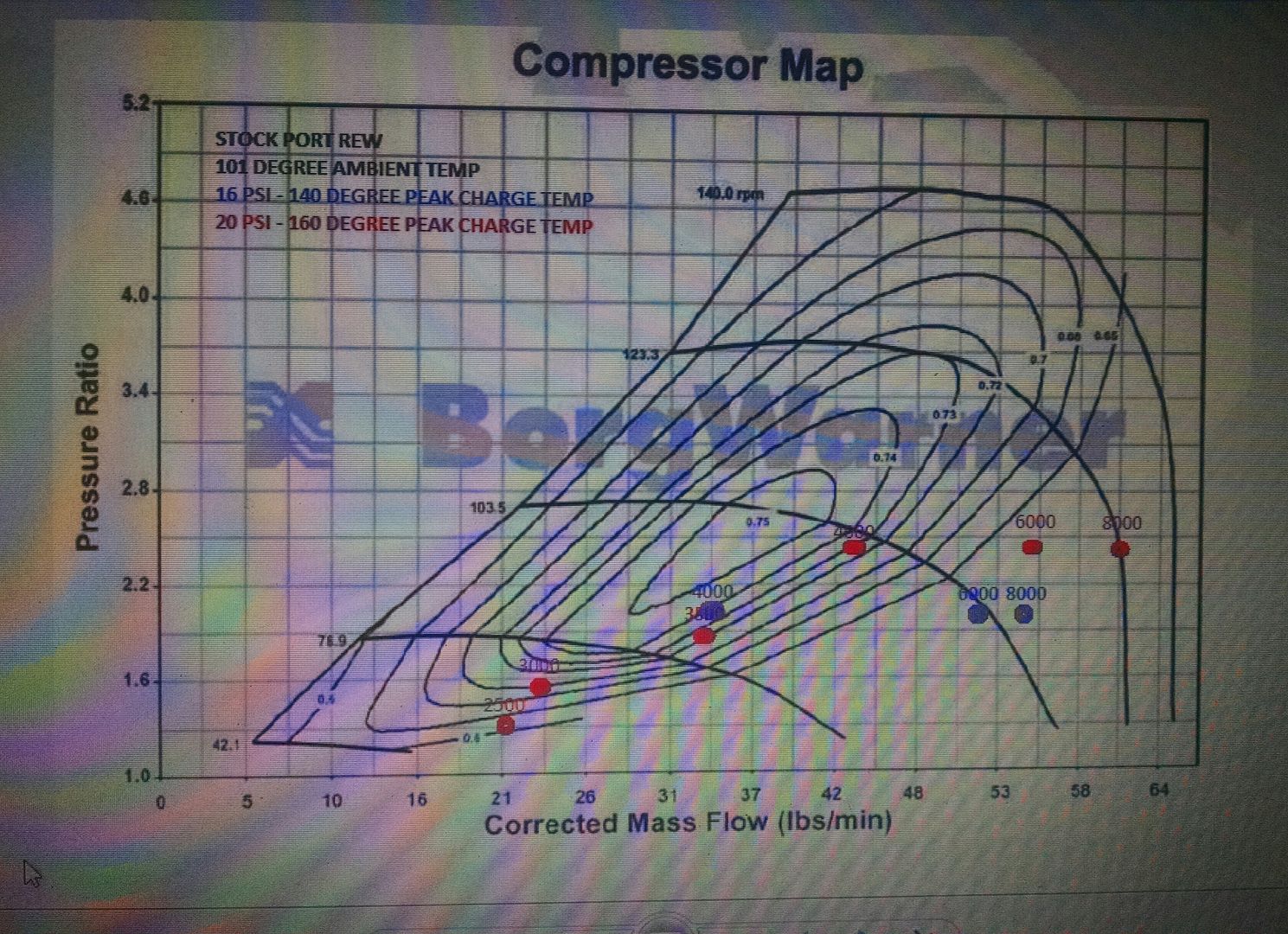

Attached a crappy cell pic of the compressor map with data points plotted. I now think more pressure wouldn't be so bad. I'm pretty sure I can setup the ECU to limit turbo speed so that it would automatically stop an overspeed condition at high revs.

I also looked at the fuel pressure data some more and FP1 and FP2 mirror each other. I may be wrong but to me that says what is happening is common to the system and we're probably seeing the same thing up at the rail. I'll move that MAP reference when I get a chance and test it.

Eric wrote:Yeah I'll probably pick up another thermostat before winter. The oil coolers definitely help, so much so that I'll either block off part of them or part of the radiator or both, for the winter.

Is there anything this ECU CAN'T do? haha I'd love to do 24psi on ethanol if we can figure out the ignition issue.

I'll move one of the sensors from the rear up to the front to test it out after I get the car back. I'm wondering if those fluctuations are due to the fuel pumps since they're so close to the pumps, and I wonder if it's not dampened more once it gets to the rail. My curiosity is going to get the better of me, I need to figure this out haha.

This is interesting regarding the fuel pulsation issue.

http://www.rx7club.com/single-turbo-rx- ... 5-1059202/Something I think I forgot to tell you, I was using the fuel pumps to drain the tank before I brought the car to you and they didn't seem like they were pumping enough fuel. But if they're supporting 450ish ethanol, I guess they're working fine. I'm not sure why they seemed inop at the time.

Chris wrote:Read that thread. PISTONS final solution was a pump voltage issue. That could be your issue but your wiring is well done and I would ASSume that couldn't be an issue.

I'll have some time tomorrow. I'm going to move the MAP reference around to see if that does anything. Also going to remove the fuel cap to make sure the tank is being vented properly. If the vent is clogged, I can see that causing the issue. Also going to crank up the sample rate in the log. Vicoor's post showing sample rate influence was interesting. Some channels on the Syvecs can be logged at up to 1000hz, so we'll crank it up and see what we get. Right now fuel pressure is probably set at 5 or 10hz.

Also, re ECU exchange. If we need to do that after you pick up the car, it will be a simple swap. All the firmware and software can be loaded on to the new box and you'll just need to plug it in and go.

Eric wrote:Yeah after I sent it to you I noticed that you had posted in there last year already. I would assume wiring is not my issue also, but who knows. I didn't read through the whole thread because it was late when I sent it.

OK sounds good! I look forward to hearing the results.

OK sounds good. I imagine they'll send the ECU straight to you and you could put the map on there. I'm not too concerned about that. Probably more-so on how long it will be until it's ready and hoping it's before I deploy again.