I ordered the clutch rebuild kit and another part for the ORC twin plate today. The overhaul kit was about $650 and the mid plate (the piece between the two friction discs that don't come with the overhaul kit) was about $145. Then I got on Atkins and got an OEM throwout bearing and pilot bearing. I had been doing some research on how to rebuild a twin plate and someone had mentioned that people should use the throwout bearing made by the company that made the clutch. I looked for it on RHDJapan and they had one for $130, and the stock one was $70. After I had already placed both orders I looked into using the aftermarket bearing and the Zilvia guys and FC guys said if you don't use the aftermarket bearing it won't work because the clutch won't disengage all the way. So I decided to not chance it and just get the ORC bearing too. I also need to get the flywheel resurfaced and get the same amount of material removed from the towers too, so I talked to CG Machine down next to Beauchamp Racing and Shogun Speed Shop. They were supposed to call me back with a quote but never did.

While I'm changing the clutch I'm going to swap oil pans, install the Noltec engine mounts again, install the Banzai tranny brace I got from Eduardo a couple years ago, and swap back to a USDM tranny.

Build thread

- speedjunkie

- Senior Member

- Posts: 5352

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

- speedjunkie

- Senior Member

- Posts: 5352

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

I did some testing yesterday and verified my oil thermostat does actually work. Although it seems like it opens around 145F and I think it's supposed to be higher than that. I did learn that using the IR thermometer on the thermostat doesn't really work haha. The temps there were about 40 degrees cooler than everywhere else. I was comparing the gauge (tapped into the oil filter pedestal), the oil thermostat, each oil cooler, and the water temp, at 5-10 degree intervals. After noticing the difference between the thermostat and everything else I decided to measure the exterior of the filter pedestal and it was 30 degrees cooler than the gauge was showing.

I got a message on RHDJapan the other night and they were requesting that I confirm the serial number on the inside of the clutch cover. So I guess I'll be removing the clutch tomorrow evening after the drive.

I got a message on RHDJapan the other night and they were requesting that I confirm the serial number on the inside of the clutch cover. So I guess I'll be removing the clutch tomorrow evening after the drive.

Re: Build thread

How did the drive go? Did you pull the transmission and clutch?

Looks like it might be a good winter for tracking if the weather continues this way.

Looks like it might be a good winter for tracking if the weather continues this way.

- speedjunkie

- Senior Member

- Posts: 5352

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

The drive was awesome! Aside from trying to get around an asshole that was purposely staying in my way coming back down 24 through the fun, curvy parts, and when I finally went to pass him the clutch slipped bad LOL. But I was going into and through the corners at 80mph so I think the car is set up really well regarding the suspension and wheels/tires. I started pulling the tranny last night but didn't get very far. I did a little more tonight but still no dice. I realized that to get the PPF off I might have to remove the diff brace/cradle and I REALLY don't want to do that. I might be able to get around it though, and possibly not even fully remove the PPF. Other than that and the actual bolts holding the tranny in it is ready to come out. Last night I started by draining all the fluids out of the engine and radiator so it would force me to move forward haha.

RHDJapan told me that ORC doesn't have a throwout bearing for the FD even though the website says they do. So I cancelled that order, but I realized I might need to get another mid plate, which is another $145.

Yeah I need to get some track days whether it's this winter or next summer. This winter is nice so far, but I'm expecting snow to hit any day now. Driving on curvy roads is fun, but I'm sick of being stuck behind other cars or worrying about hitting the canyon wall or something.

RHDJapan told me that ORC doesn't have a throwout bearing for the FD even though the website says they do. So I cancelled that order, but I realized I might need to get another mid plate, which is another $145.

Yeah I need to get some track days whether it's this winter or next summer. This winter is nice so far, but I'm expecting snow to hit any day now. Driving on curvy roads is fun, but I'm sick of being stuck behind other cars or worrying about hitting the canyon wall or something.

Re: Build thread

Well depending on the track day, it may not be a lot better. There are slow people like me out there to. You have the HP/Torque to pull easily on us in the straights though.

They are a ton of fun. Winter track day we did in Pueblo was tons of fun. I don' recall a lot of cars on track. Afternoons always get light, so chilling out and learning the course early, then waiting to really try to turn fast laps seems like a plan.

They are a ton of fun. Winter track day we did in Pueblo was tons of fun. I don' recall a lot of cars on track. Afternoons always get light, so chilling out and learning the course early, then waiting to really try to turn fast laps seems like a plan.

- speedjunkie

- Senior Member

- Posts: 5352

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

What are you talking about, I've never been to a track day. You really think I'm gonna be any faster than you or anyone else out there? Lol And CERTAINLY not as good a driver on track.

- speedjunkie

- Senior Member

- Posts: 5352

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

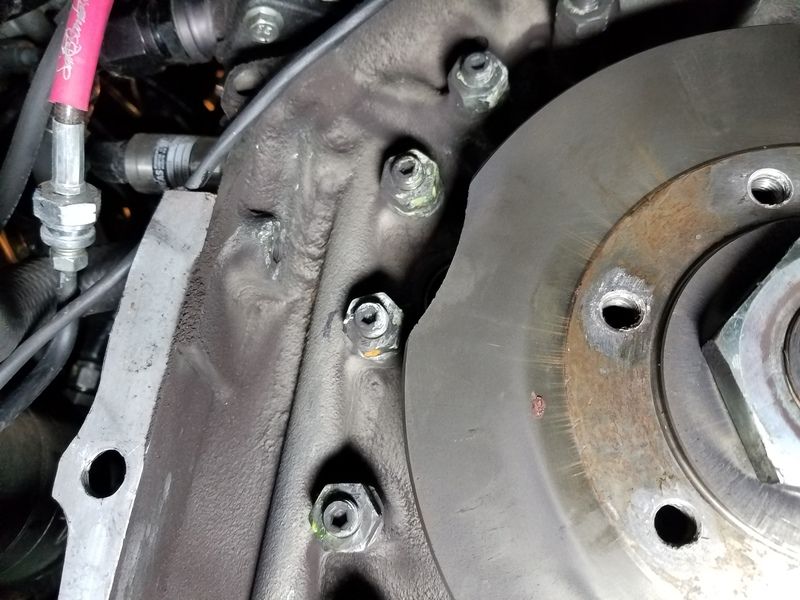

I got the tranny and clutch out this afternoon. The tranny came out super easy, I didn't have to remove the diff brace/cradle or the PPF fully. I'm waiting to hear back from RHDJapan on whether the parts I ordered are correct or if I'm screwed and have to get a whole new clutch. The other mid plate I was thinking I'd need is either the crown or the pressure plate, I'm still trying to figure that out. Either way I don't see it for sale separately on their site.

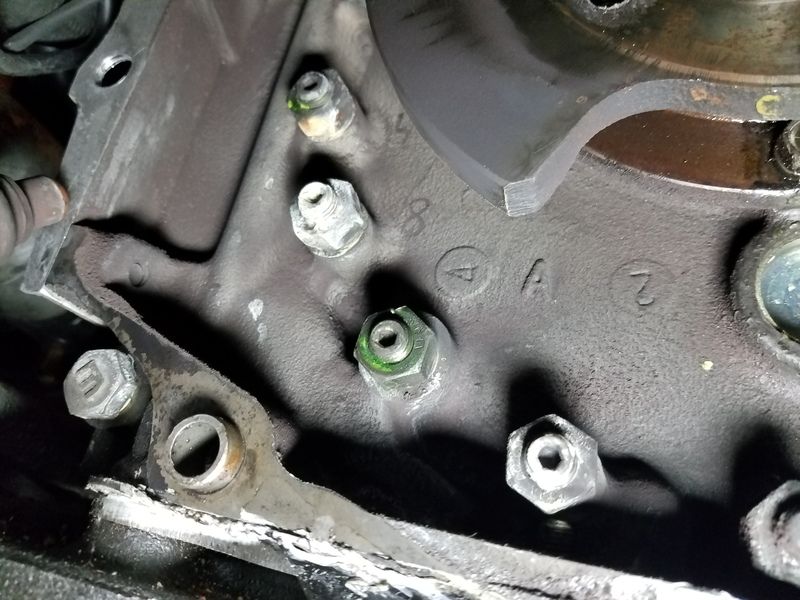

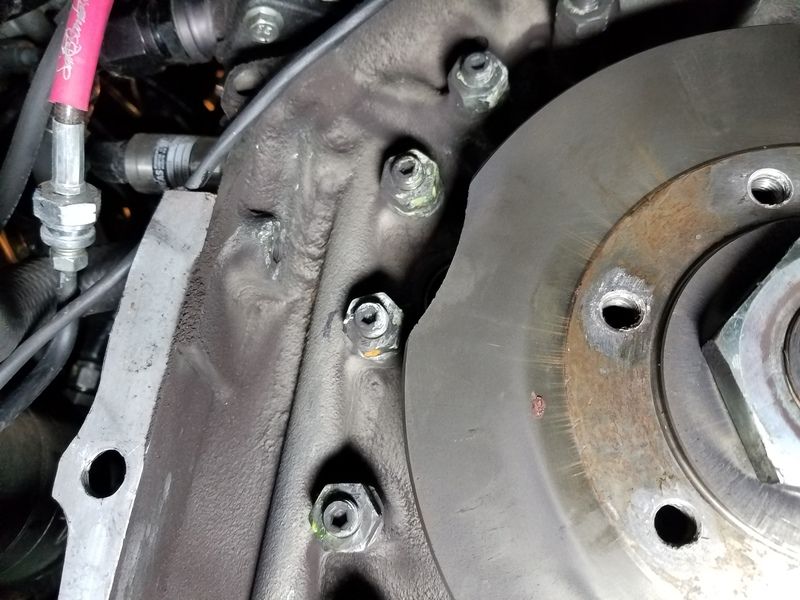

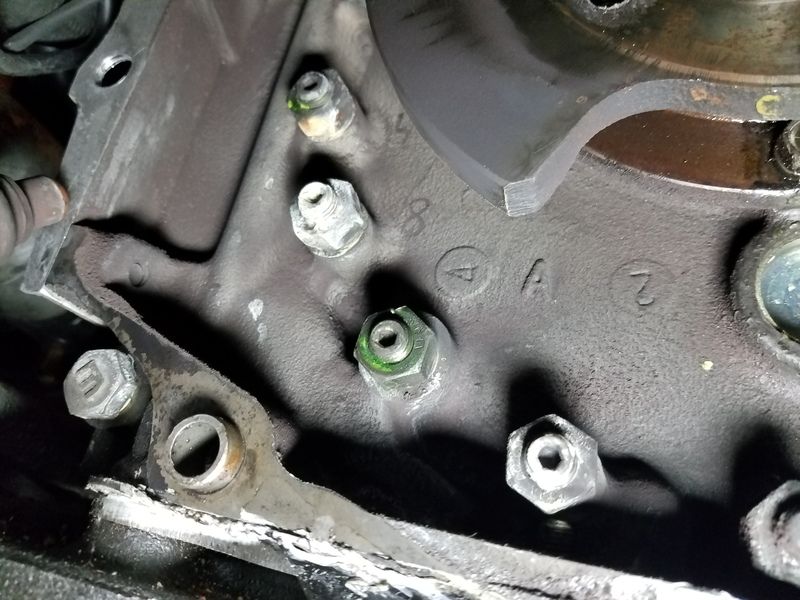

Also, I'm really hoping not but I might have to rebuild the engine again. I've noticed before that there was coolant residue on the bottom edge of the bell housing, and after removing the flywheel I noticed where it's coming from.

Also, I'm really hoping not but I might have to rebuild the engine again. I've noticed before that there was coolant residue on the bottom edge of the bell housing, and after removing the flywheel I noticed where it's coming from.

Re: Build thread

Your clutch situation sounds like a bit of a headache. Now that you have it apart, can you tell if your friction surface is bad? I've never dealt with a clutch that has as many plates as you are discussing. I took a gander at RHD Japan and the ORC 559cc twin disc came up. Hopefully you don't need to buy the whole thing ($1,900.00!). Not sure that is even the right clutch, but holy cow is that expensive.

Hoping you don't need to rebuild your engine. Would that be a matter of getting all new seals, tearing it down and putting them in? Any chance a seal just got stuck similar to chickenwafer's situation with the REPU?

I'm going to have to look pretty far out for my next track day, so we should try to coordinate to get to the same one. I've only driven at Pueblo once (first track day) and HPR 3 times. A handful of autocross events. I have taken a bunch of rides at HPR which has been very helpful. I'm planning to go out there anytime I know someone there to catch some rides while my shoulder is recovering. Riding with DWDUC is the best because I'm on the side I would normally be on while driving and the lines look the same. He also has a very good handle on the corners I really chicken out of.

Hoping you don't need to rebuild your engine. Would that be a matter of getting all new seals, tearing it down and putting them in? Any chance a seal just got stuck similar to chickenwafer's situation with the REPU?

I'm going to have to look pretty far out for my next track day, so we should try to coordinate to get to the same one. I've only driven at Pueblo once (first track day) and HPR 3 times. A handful of autocross events. I have taken a bunch of rides at HPR which has been very helpful. I'm planning to go out there anytime I know someone there to catch some rides while my shoulder is recovering. Riding with DWDUC is the best because I'm on the side I would normally be on while driving and the lines look the same. He also has a very good handle on the corners I really chicken out of.

- speedjunkie

- Senior Member

- Posts: 5352

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

Yeah I'm not a fan of this situation either lol. The clutch overhaul kit is about $650 or so, and the mid plate was $145. If I end up having to get a new clutch I might just go back to a single plate. Apparently the twin plates don't hold much torque. I don't know how they compare to a single plate though. They're checking now to see if the parts I ordered are going to work for me. If so I'll take the flywheel to get resurfaced tomorrow.

My buddy I was stationed with in Okinawa told me the coolant issue is a sign of bad water seals, although I'm not sure if that means compression is pushing the coolant out past the studs. The studs go through the coolant jacket so they're going to have coolant on them anyway, but if the inner water seals are bad I guess compression could push it out past the studs. However, if that's the problem then the champagne test should confirm it. Unfortunately I already drained the coolant and oil so I can't do that test unless I refill them and I don't really want to do that until putting the engine back in. But if that's what it takes, maybe I'll do that anyway. Basically, if it's the water seals I'll buy just those and reuse everything else as long as the rest is good. And it won't take long to rebuild that way either. Dave's issue was a stuck apex seal. Mine could be a water seal, so it may have pinched or something when building the engine.

Yeah I haven't done any of that lol. No ride alongs, no autocross, no road course..., so I'm sure you got me hands down haha. I need to ride with Jason too, that makes perfect sense. I'd love to do a track day with all of us though at some point.

I think I might gut the FC and make it the track car, or make it an additional one haha.

UPDATE: After posting on facebook one of the guys told me that when studs are used you're supposed to put silicone on the threads so coolant doesn't seep out through the threads. That makes perfect sense since the head on the stock bolts hold the coolant in, and I'll be adding either silicone or RTV while the engine is out. That should fix the problem.

My buddy I was stationed with in Okinawa told me the coolant issue is a sign of bad water seals, although I'm not sure if that means compression is pushing the coolant out past the studs. The studs go through the coolant jacket so they're going to have coolant on them anyway, but if the inner water seals are bad I guess compression could push it out past the studs. However, if that's the problem then the champagne test should confirm it. Unfortunately I already drained the coolant and oil so I can't do that test unless I refill them and I don't really want to do that until putting the engine back in. But if that's what it takes, maybe I'll do that anyway. Basically, if it's the water seals I'll buy just those and reuse everything else as long as the rest is good. And it won't take long to rebuild that way either. Dave's issue was a stuck apex seal. Mine could be a water seal, so it may have pinched or something when building the engine.

Yeah I haven't done any of that lol. No ride alongs, no autocross, no road course..., so I'm sure you got me hands down haha. I need to ride with Jason too, that makes perfect sense. I'd love to do a track day with all of us though at some point.

I think I might gut the FC and make it the track car, or make it an additional one haha.

UPDATE: After posting on facebook one of the guys told me that when studs are used you're supposed to put silicone on the threads so coolant doesn't seep out through the threads. That makes perfect sense since the head on the stock bolts hold the coolant in, and I'll be adding either silicone or RTV while the engine is out. That should fix the problem.

- chickenwafer

- Posts: 2515

- Joined: Wed Mar 11, 2009 9:14

- Location: Greeley

Re: Build thread

Do the studs still use the o-rings like the tension bolts? If not then that would certainly cause a leak like that.

Re: Build thread

I didn't know you had an fc too.

Hope silicone is the answer.

Hope silicone is the answer.

- speedjunkie

- Senior Member

- Posts: 5352

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

chickenwafer wrote:Do the studs still use the o-rings like the tension bolts? If not then that would certainly cause a leak like that.

Yeah I'm still using those washers but the rubber inner part on them isn't in very good shape as it turns out.

Shadowden wrote:I didn't know you had an fc too.

Hope silicone is the answer.

Yeah I got it in early 2008, right before I moved out here. I traded my 97 Prelude to my buddy for it and a 95 Jetta which disappeared years ago after I gave it to Zico and I deployed and he went to Hawaii. It wasn't here when we got back haha. Anyway, the FC hasn't ran since 2007 due to a cracked rear iron, it sprays oil while running. I have the parts to fix it, I just never have gotten around to it.

Well it's actually RTV. One of the guys said silicone but I figured he meant RTV because silicone wouldn't actually seal anything.

The other day I started getting the engine ready to pull. I removed the turbo and manifold and discovered that only one of the bolts was really tight. YIKES. The other three were not much more than finger tight. Then I discovered another problem. Turns out one of my trailing spark plug wires was arcing to the engine. So I'll be making a new one I guess.

I got the engine out tonight and got all the tension studs sealed. It took a good hour and a half at least, probably a couple hours. I had some issues with some of them because the RTV wouldn't stick if there was any coolant present, so I gooped the shit out of them after lol. I took the nuts and washers off, applied RTV around the stud where it drops into the engine, then pushed the washer on and used some of the excess to put on the threads, then I torqued the nut back on and used RTV on the end of the nut and exposed threads, and put some more at the base of the nut and washer if it needed it. That better do it lol.

So this getup is what Chris had to do to incorporate a fuel pulsation damper into the system. It takes up a bit of space, but so far I haven't found anything simpler or smaller. Tonight I saw that Radium sells one that is a rising rate damper, but I'm not sure if I can make it work with the available thread pitches they have, not without it being just as bulky as this one.

I'm going to take this filler neck to get powder coated tomorrow since it has one less hole to plug than my current one lol. And I'm picking up a set screw from Brad to plug where the level sensor used to go also.

I got an email from RHDJapan tonight saying that my order will be shipping soon. This after talking to them for almost two weeks trying to hash out if what I ordered was going to work with my current setup. Friday I took the flywheel to CG Machine only to have them tell me they couldn't resurface it after all. Since Beauchamp Racing was next door I stopped to see Tom and he had be remove the posts and he took an abrasive disc and scuffed the contact area right then and there. Then he said I could do that to the mid plate and pressure plate as well, and as long as the friction discs had enough life on them I could sand blast them and reuse everything. Well dammit lol. That's $800 I could have saved right there, because I'm pretty sure my discs are still good. The both have almost .150" left and they're not worn until about .100. Anyway, Tom said I just glazed them because I'm trying to drive it like a regular car and I have to just drop the clutch and let it grab instead of slipping it. I think I'm going back to a single plate next time, something that's more normal for the street.

I also bought a doorway welt strip and the hood seal from a guy on 7club. And I'm dropping off the exhaust stuff tomorrow at Applied Plastics in Denver so I can get them ceramic coated again. I'm going to swap the oil pan tomorrow and try to drop the engine back in. I measured the delrin engine mounts and pan brace and compared it to the Noltec mounts I'm putting back in with the new oil pan. It looks like the new setup will sit about 7mm higher, which will probably make the UIM touch the strut bar. Sigh.

Re: Build thread

What is the advantage to the Nolte mounts over the existing Delrin mounts? Seems like you would want to get the engine as low as possible to lower the center of gravity. Any issues with changing angles of other things as well?

- speedjunkie

- Senior Member

- Posts: 5352

- Joined: Wed Jan 02, 2008 9:14

- Location: Colorado Springs

- Contact:

Re: Build thread

The Noltec mounts are polyurethane so they're not quite as harsh as the Delrin mounts, although I don't really care so much about that. I can feel a little vibration in the gas pedal with the Delrin mounts, that's about it.

The main reason I want to change back is because I want to install the tranny brace I bought from Eduardo a couple years ago but with the engine sitting lower it won't fit right. And I'll also be able to ditch the shims I've been using on the diff brace. The shorter mounts basically throw off the whole driveline. But I might end up leaving the Delrin mounts in and maybe see if I can shim the tranny brace too, or just not use it.

Another thing is the Delrin mounts might drop the oil pan lower to the ground than I'd like.

The main reason I want to change back is because I want to install the tranny brace I bought from Eduardo a couple years ago but with the engine sitting lower it won't fit right. And I'll also be able to ditch the shims I've been using on the diff brace. The shorter mounts basically throw off the whole driveline. But I might end up leaving the Delrin mounts in and maybe see if I can shim the tranny brace too, or just not use it.

Another thing is the Delrin mounts might drop the oil pan lower to the ground than I'd like.

- chickenwafer

- Posts: 2515

- Joined: Wed Mar 11, 2009 9:14

- Location: Greeley

Re: Build thread

Your pace puts mine to shame LOL. Engine in and out in hours!

Who is online

Users browsing this forum: No registered users and 38 guests