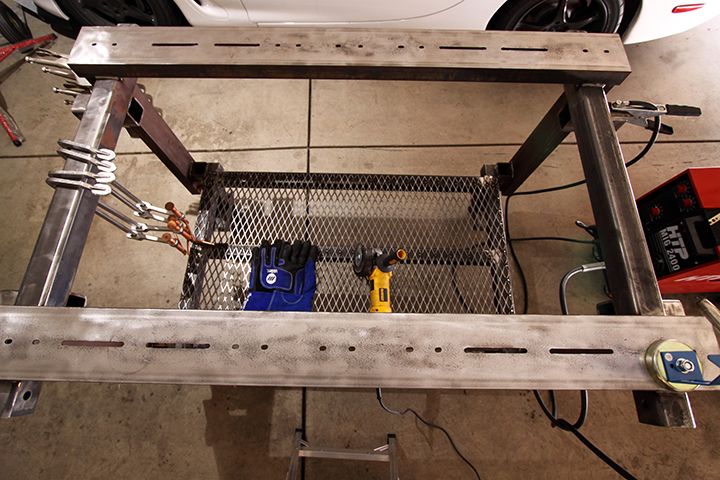

Here's the 5/8" thick steel, 80+ pound weapon of mass destruction:

speedjunkie wrote:Refresh my memory, what will this be used on?

Shadowden wrote:I need to come see your shop!

Nice work on that base!

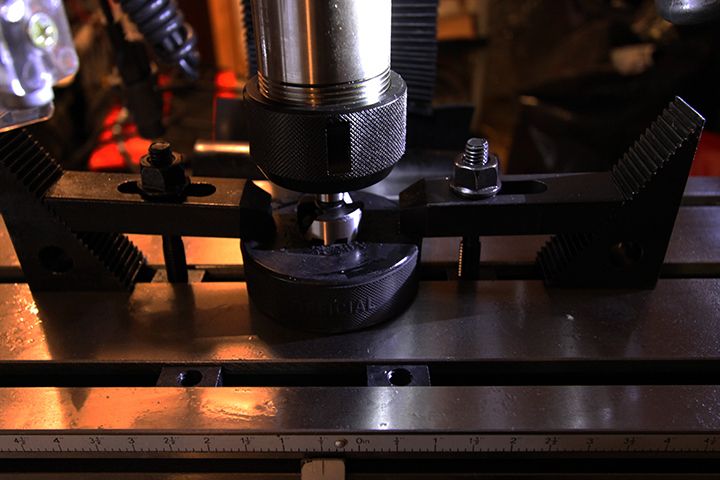

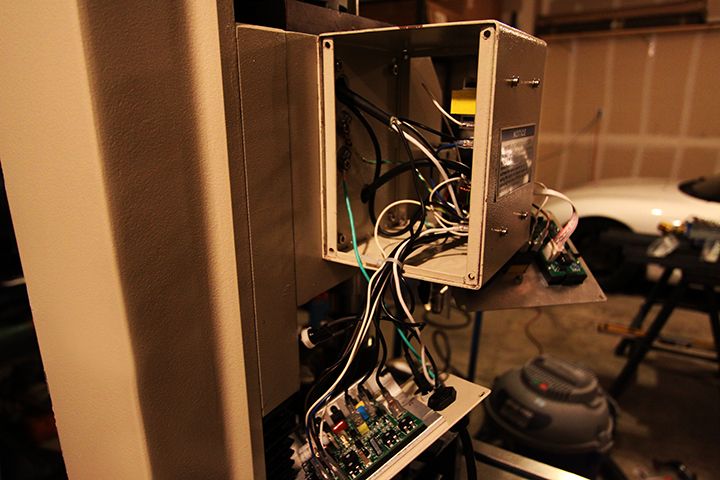

Dwduc wrote:Nice new toys! with the CNC are you going to use a servo or stepper set up? Also I recommend converting to ball screw at the same time. I know mine has been quite a learning experience.

Also what program are you planning to use to control it? I had an older TMG (The Motion Group) controller that was nothing but trouble and recently converted to Mach 3 and love it.

speedjunkie wrote:Nice! I like the sliding pieces for the table top, that way it's flexible for different projects. You can still slide them all together for a good size tabletop if you need them together, or you can slide them apart. That's a great idea.

Shadowden wrote:Have you tried the scotch brite pads for angle grinders? They knock down mill scale pretty well and leave a nice finish. You really need it for a welding table top though. An advantage to the pads is that you are unlikely to dig into the table top.

How did you anchor the top pieces to the channel? Did you make a mounting place to mount the extra two slats when you are in the 7- panel configuration? Great work on that table!

1/2" would be great. That is a lot of steel to drill through though. I don't weld anything really heavy so was considering 3/8" myself. Would like to get your impressions once you use it some.

FDEEZ wrote:speedjunkie wrote:Nice! I like the sliding pieces for the table top, that way it's flexible for different projects. You can still slide them all together for a good size tabletop if you need them together, or you can slide them apart. That's a great idea.

I appreciate it, thanks! Btw, I can't wait to see your car back on the road. It's definitely a top notch, high quality build. I'm still not sure if you're building a show car or a race car, lol

FDEEZ wrote:Shadowden wrote:Have you tried the scotch brite pads for angle grinders? They knock down mill scale pretty well and leave a nice finish. You really need it for a welding table top though. An advantage to the pads is that you are unlikely to dig into the table top.

How did you anchor the top pieces to the channel? Did you make a mounting place to mount the extra two slats when you are in the 7- panel configuration? Great work on that table!

1/2" would be great. That is a lot of steel to drill through though. I don't weld anything really heavy so was considering 3/8" myself. Would like to get your impressions once you use it some.

I've used the scotch brite pads (both the AvantiPro & 3M) for this table. They easily stripped the mill scale on everything except those 6" plates. The mill scale on those plates are unbelievably thick (which is why I dipped them in muriatic acid). I went through several of those strip discs...but after a while, it starting getting expensive. After the scotch brite, I switched to muriatic acid, then 80 grit flap discs, then trying out 80 grit on my belt sander, then 100 grit when the 80 grit broke, then back to 80 grit flap discs.

I used 1.5" x 5/8" socket/allen drive countersunk head screws to secure the plates to the c-channel. Surprisingly, there was about a 40 cent difference in price between a 1" long screw from the Ace Hardware in Stetson Hills and a 1.5" long screw at the Ace Hardware in Austin Bluffs (for those local to COS). What's surprising was that the 1.5" long screw was 40 cents cheaper (Austin Bluffs) than the 1" screw (Stetson Hills). Alas, I went with the 1.5" long ones due to price.

As far as the extra 2 plates (when in 7 plate mode), I haven't built anything to accommodate them (yet). For now, I'll probably just lay them on the shelf under the table.

Things I would change if I could do it all over again:

1. Cold-rolled 1/2" plate instead of the hot-rolled steel I used

2. 5" c-channel for the legs (for a cleaner look)

3. Add gussets for the receiver hitches (which I still might add)

4. Use the "Safer to Use" muriatic acid...and use a gas/face mask approved for this stuff

-- I wouldn't recommend this stuff without the proper safety PPE. This stuff (at full strength) is BAD!!! The pros don't outweigh the cons, IMHO.

Shadowden wrote:Should pull this outside your car thread!

I had considered doing something similar to your table, but having the plates always separated for clamping or doing a solid top and drilling and tapping evenly spaced holes for adding fixtures to clamp to. I like that you can make a solid table top. I could drill and tap the holes to add fixturing or open up slats for clamping as I see the need to. I was going to use I beams instead of channel to hold the plate , but I also like the idea of channel better. Did you just thread the channel or did you tack a nut to the underside? I was planning to tack a nut there.

what saw are you using? I sold my Ridgid abrasive chop saw and was planning on buying an Evolution Rage2 cold cut. I fear space required for a band saw may be limiting.

Users browsing this forum: No registered users and 28 guests